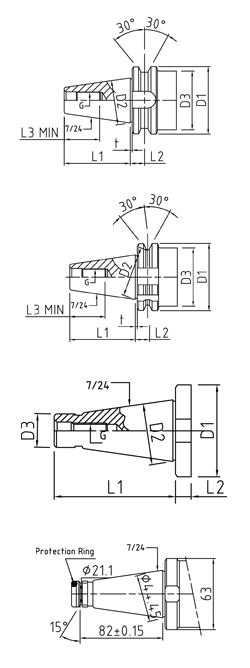

Taper Shank Specifications

| TAPER SHANK SPECIFICATION :: BT - MAS403 |  |

||||||||

| Taper | D1 h 8 | D2 | D3 | L1+0.2 | L2+0.1 | G | L3 Min | t | |

| 30 | 46 | 31.75 | 38 | 48.4 | 13.6 | M12 | 24 | 2 | |

| 35 | 53 | 38.1 | 43 | 56.4 | 13 | M12 | 24 | 2 | |

| 35MAS | 53 | 38.1 | 43 | 56.4 | 14.6 | M12 | 27 | 2 | |

| 40 | 63 | 44.45 | 53 | 65.4 | 16.6 | M16 | 30 | 2 | |

| 45 | 85 | 57.15 | 73 | 82.8 | 21.2 | M20 | 38 | 3 | |

| 50 | 100 | 69.85 | 85 | 101.8 | 23.2 | M24 | 45 | 3 | |

| TC / SK - DIN 69871 / ISO 7388 DIMENSIONS ARE IN MM | |||||||||

| Taper | D1h 8 | D2 | D3 | L1+0.2 | L2+0.1 | G | L3 Min | t | |

| 30 | 50 | 31.75 | 45 | 47.8 | 11.1 | M12 | 26 | 3.2 | |

| 40 | 63.55 | 44.45 | 50 | 68.4 | M16 | 32 | |||

| 45 | 82.55 | 57.15 | 63 | 82.7 | M20 | 40 | |||

| 50 | 97.5 | 69.85 | 80 | 101.75 | M24 | 47 | |||

| ISO DIN 2080 ( FOR CONVENTIONAL M / C ) | |||||||||

| Taper | D1h 8 | D2 | D3 | L1 | L2 | a | G | ||

| 30 | 50 | 31.75 | 17.4 | 70 | 8 | 1.6 | M12 | ||

| 40 | 63 | 44.45 | 25.3 | 95 | 10 | 1.6 | M16 | ||

| 45 | 80 | 57.15 | 32.4 | 110 | 12 | 3.2 | M20 | ||

| 50 | 97.5 | 69.85 | 39.6 | 130 | 12 | 3.2 | M24 | ||

| ISO DIN 2080 (FOR CNC M/C) | |||||||||

| UNIVERSAL TYPE SUITABLE FOR | |||||||||

| Conventional & CNC Milling Machines with Draw Bar | |||||||||

| CNC Milling Machines like deckel mickron, maho fitted with Hydraulic clamping arrangement | |||||||||