Products and Services

LBX:

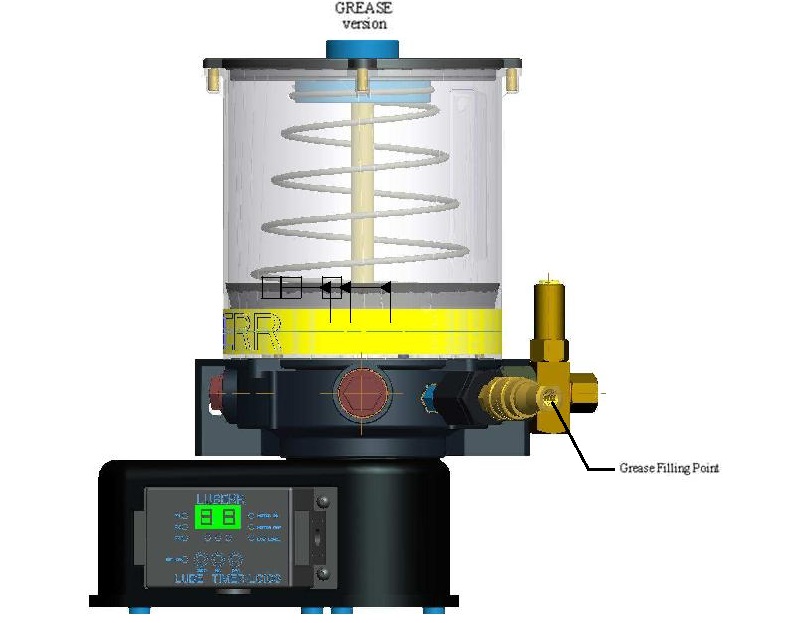

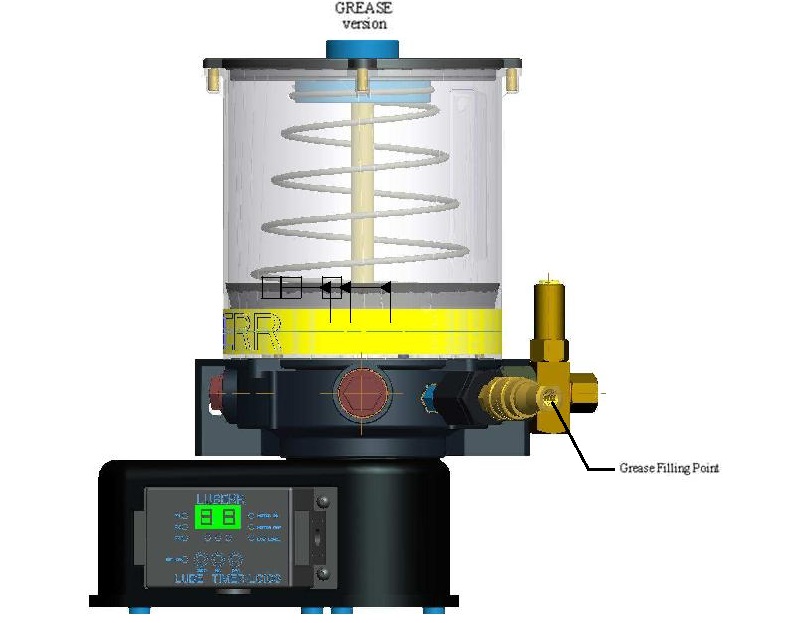

LBX – LUBERR DELUX is a DC operated piston pump with the pumping element. It runs from a camshaft connected to a motor box. It can be fitting with up to 3 pumping elements which are available with a PRV (pressure relief valve).

LBX – LUBERR DELUX is a DC operated piston pump with the pumping element. It runs from a camshaft connected to a motor box. It can be fitting with up to 3 pumping elements which are available with a PRV (pressure relief valve).

The main body of the pump is made from high performance robust plastic and is compact in size designed to withstand tough environments.

The grease version of the LUBERR LBX includes a stirrer device with atop covered reservoir wiper that helps to eliminate air present in the grease and facilitate pumping even at lower temperatures.

The DC geared motor drive arrangement, is controlled remotely in the manual version or via the built in control system in the automatic version.

LDX:

LDX:

LUBERR DX is a DC operated piston pump with the pumping element. It runs from a camshaft connected to a motor box. It can be fitting with up to 3 pumping elements which are available with a PRV (pressure relief valve). The pumping unit plunger sucks the grease from the reservoir and is forced out by pumping unit plunger movement. By this pressure, the grease is forced out from the outlet to the distributors inlet and finally to greasing points. LDX has different reservoir compare to LBX.

LUBERR DX is a DC operated piston pump with the pumping element. It runs from a camshaft connected to a motor box. It can be fitting with up to 3 pumping elements which are available with a PRV (pressure relief valve). The pumping unit plunger sucks the grease from the reservoir and is forced out by pumping unit plunger movement. By this pressure, the grease is forced out from the outlet to the distributors inlet and finally to greasing points. LDX has different reservoir compare to LBX.

The main body of the pump is made from high performance robust plastic and is compact in size designed to withstand tough environments.

The grease version of the LUBERR DX includes a stirrer device with a reservoir wiper that help to eliminate air present in the grease and facilitate pumping even at lower temperatures.

The DC geared motor drive arrangement, is controlled remotely in the manual version or via the built in control system in the automatic version.

LFX:

LFX:

LUBERR FX is a DC operated piston pump with the pumping element. It runs from a camshaft connected to a motor box. It can be fitting with up to 3 pumping elements which are available with a PRV (pressure relief valve).

LUBERR FX is a DC operated piston pump with the pumping element. It runs from a camshaft connected to a motor box. It can be fitting with up to 3 pumping elements which are available with a PRV (pressure relief valve).

The main body of the pump is made from high performance robust plastic and is compact in size designed to withstand tough environments.

The grease version of the LUBERR FX includes a reservoir follower assembly that helps to push the grease and facilitate pumping even at lower temperatures.

The DC geared motor drive arrangement, is controlled remotely in the manual version or via the built in control system in the automatic version.

LCX:

CART LUBERR is a DC operated piston pump with the pumping element. It runs from a camshaft connected to a motor box. It can be fitting with up to 30 pumping elements which available without a PRV (pressure relief valve).

CART LUBERR is a DC operated piston pump with the pumping element. It runs from a camshaft connected to a motor box. It can be fitting with up to 30 pumping elements which available without a PRV (pressure relief valve).

The main body of the pump is made from high performance robust plastic and is compact in size designed to withstand tough environments.

The grease version of the CART LUBERR that helps to eliminate dust particle present in the grease and facilitate pumping even at lower temperatures. This version has come with cartridges which contains 1.5 kg amount of grease and replaceable one.

The DC geared motor drive arrangement, is controlled remotely in the manual version or via the built in control system in the automatic version.

OLDX:

OCTO LUBERR is a DC operated piston pump with the pumping element. It runs from a camshaft connected to a motor box. It can be fitting with up to 32 pumping elements. This pump has 4 different varieties of pumping units.

OCTO LUBERR is a DC operated piston pump with the pumping element. It runs from a camshaft connected to a motor box. It can be fitting with up to 32 pumping elements. This pump has 4 different varieties of pumping units.

The main body of the pump is made from high performance Aluminum and is compact in size designed to withstand tough environments.

The grease version of the OCTO LUBERR includes a stirrer device with a reservoir wiper that helps to eliminate air present in the grease and facilitate pumping even at lower temperatures.

The DC geared motor drive arrangement, is controlled remotely in the manual version or via the built in control system in the automatic version.

LBA:

LBA:

The LUBERR LBA-3 is a 3 phase AC motorised operated grease pump. LBA-3 is high pressure pump delivering commercial greases up to NLGI class-2. This is a reciprocating type pump carries the lubricating grease to the lubricating point via a progressive distributor or injectors. It is suitable for operating with mineral oil and grease upto a consistency of NLGI grade-2.

It must be ensured that the oil or grease used do not have a tendency to change their consistency-significantly in the course of time or under the influence of temperature or pressure. There can be a maximum of 3 pumping units fitted on the pump. The output from each pumping unit can be fed to the progressive distributors or injectors to various greasing points on the machinery.

MOTOLUBERR:

The MOTOLUBERR is a motorized operated grease pump. It is a high pressure pump delivering commercial greases up to NLGI class-2. This is a reciprocating type pump carries the lubricating grease to the lubricating point via a progressive distributor or injectors. It is suitable for operating with mineral oil and grease upto a consistency of NLGI grade-2. It must be ensured that the oil or grease used do not have a tendency to change their consistency-significantly in the course of time or under the influence of temperature or pressure.

The eccentric movements in pump body push the pump elements pistons and pull as return. This pumping action sucks the grease from the reservoir to pump via suction pipe and is pressurized by piston movement. By this pressure the grease is forced out from the outlet thru the greasing gun or distributors and finally to greasing points. Pumps are made for lubrication purposes only and cannot run continuously over 2 hours. The pump can be used with Progressive distributors / Injectors on any machinery to lubricate various bearing.

MLA:

The MOTOLUBERR MLA-3 is a 3 phase AC motorised operated grease pump.

MLD:

The MOTOLUBERR MLD (Motoluberr Deluxe) is a DC operated grease pump. Motor type is 24 VDC geared motor (15 Amps rated). It has different capacity 20 kg and 50 kg reservoir. Its maximum working pressure is 300 bars. MLD comes without low level indicator (standard), with low level indicator, with low level switch. Motoluberr Deluxe contains Timer control unit or SMPS 230 VAC converter. Here serial line distributing systems are used.

The MOTOLUBERR MLD (Motoluberr Deluxe) is a DC operated grease pump. Motor type is 24 VDC geared motor (15 Amps rated). It has different capacity 20 kg and 50 kg reservoir. Its maximum working pressure is 300 bars. MLD comes without low level indicator (standard), with low level indicator, with low level switch. Motoluberr Deluxe contains Timer control unit or SMPS 230 VAC converter. Here serial line distributing systems are used.

MLI:

The MOTOLUBERR MLI (Motoluberr with Injector) is a DC operated grease pump. Motor type is 24 VDC geared motor (15 Amps rated). It has capacity of 25 kg reservoir. Its maximum working pressure is 300 bars. MLD comes without low level indicator (standard), with low level indicator, with low level switch. Motoluberr with Injector system contains Timer control unit or SMPS 230 VAC converter. Here parallel line injector systems are used.

The MOTOLUBERR MLI (Motoluberr with Injector) is a DC operated grease pump. Motor type is 24 VDC geared motor (15 Amps rated). It has capacity of 25 kg reservoir. Its maximum working pressure is 300 bars. MLD comes without low level indicator (standard), with low level indicator, with low level switch. Motoluberr with Injector system contains Timer control unit or SMPS 230 VAC converter. Here parallel line injector systems are used.

MLG:

The MOTOLUBERR MLG (Motoluberr Garage) is a DC operated grease pump. Motor type is 24 VDC geared motor (15 Amps rated). It has different capacity 20 kg and 50 kg reservoir. Its maximum working pressure is 300 bars. MLG comes without low level indicator (standard), with low level indicator, with low level switch. Motoluberr Garage contains Timer control unit, SMPS 230 VAC converter or ON/OFF switch. Especially this pump is useful for refilling the Grease pump (LUBERR) in Industries/ Garages where stationary filling required.

OXL:

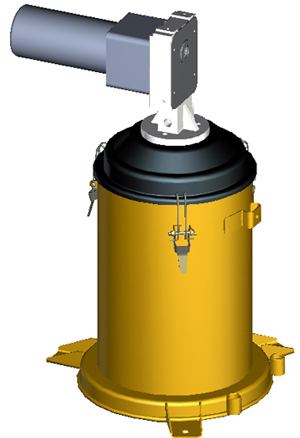

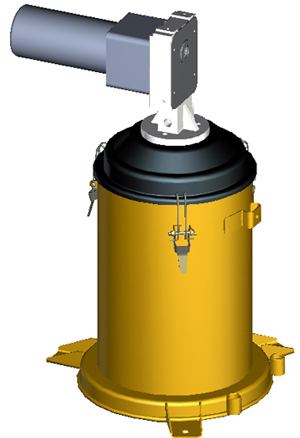

OXYLUBERR is developed by Rikkon Lubes to provide reliable and efficient Lubrication Systems on mobile application (mining Industry). OXYLUBERR was developed keeping in mind various kinds of Ambient. LUBERR has been tested at -10 deg C to +70 deg C. OXYLUBERR is tested at harshest of environment like most dusty and terrain. This pump is a PNEUMATICALLY Operated High Pressure Grease pump. OXYLUBERR has max 1 output and has a grease holding capacity of 50 kgs. It is a 50:1 ratio pump capable of pumping grease upto 100 mts long distance. The size of the pump is ideally designed to reduce the air consumption during operation. OXYLUBERR comes with Quick Fill fitted at the bottom of the reservoir.

OXYLUBERR is developed by Rikkon Lubes to provide reliable and efficient Lubrication Systems on mobile application (mining Industry). OXYLUBERR was developed keeping in mind various kinds of Ambient. LUBERR has been tested at -10 deg C to +70 deg C. OXYLUBERR is tested at harshest of environment like most dusty and terrain. This pump is a PNEUMATICALLY Operated High Pressure Grease pump. OXYLUBERR has max 1 output and has a grease holding capacity of 50 kgs. It is a 50:1 ratio pump capable of pumping grease upto 100 mts long distance. The size of the pump is ideally designed to reduce the air consumption during operation. OXYLUBERR comes with Quick Fill fitted at the bottom of the reservoir.

OXYLUBERR can be controlled using a Controller which can be fitted at a distant convenient location. Output from OXYLUBERR is distributed to various points using SVM 21 Progressive Distributors (for series system) or SVM01 INJECTORS (for parallel System).

SVM 21:

The Rikkon Lube Progressive Distributor Model SVM 21DV are plunger operated distributors suitable for operating with mineral oil and grease upto a consistency of NLGI grade-2. It must be ensured that the oil or grease used do not have a tendency to change their consistency-significantly in the course of time or under the influence of temperature or pressure. These plunger displacement distributors automatically (Progressively) deliver the lubricant fed by the pump into preset individual volumes to the connected lubrication point.

MODE OF OPERATION

The Rikkon Lube Progressive Distributor Model SVM 23A are plunger operated distributors suitable for operating with mineral oil and grease upto a consistency of NLGI grade-2. It must be ensured that the oil or grease used do not have a tendency to change their consistency-significantly in the course of time or under the influence of temperature or pressure. These plunger displacement distributors automatically (Progressively) deliver the lubricant fed by the pump into preset individual volumes to the connected lubrication point.

MODULAR PROGRESSIVE DISTRIBUTOR SVM 23A

MODE OF OPERATION

MODE OF OPERATION

SVM53 -SPRAY SYSTEM:

The Rikkon Lube spray Pump Model SVM53 is compact pump which spray oil up to cst100. This is a reciprocating type pump which carries the oil to the lubricating point via a coaxial tube. The air passes thru the solenoid valve to the pump outlet and travels along with the oil in the coaxial tube. The air and oil gets mixed at the end of the coaxial tube where the lubricant to be sprayed. Capacity of the reservoir is 2.0Lts. Larger capacity reservoirs can be provided on request.

The Rikkon Lube spray Pump Model SVM53 is compact pump which spray oil up to cst100. This is a reciprocating type pump which carries the oil to the lubricating point via a coaxial tube. The air passes thru the solenoid valve to the pump outlet and travels along with the oil in the coaxial tube. The air and oil gets mixed at the end of the coaxial tube where the lubricant to be sprayed. Capacity of the reservoir is 2.0Lts. Larger capacity reservoirs can be provided on request.

SALIENT FEATURES:

LBX – LUBERR DELUX is a DC operated piston pump with the pumping element. It runs from a camshaft connected to a motor box. It can be fitting with up to 3 pumping elements which are available with a PRV (pressure relief valve).

LBX – LUBERR DELUX is a DC operated piston pump with the pumping element. It runs from a camshaft connected to a motor box. It can be fitting with up to 3 pumping elements which are available with a PRV (pressure relief valve).

The main body of the pump is made from high performance robust plastic and is compact in size designed to withstand tough environments.

The grease version of the LUBERR LBX includes a stirrer device with atop covered reservoir wiper that helps to eliminate air present in the grease and facilitate pumping even at lower temperatures.

The DC geared motor drive arrangement, is controlled remotely in the manual version or via the built in control system in the automatic version.

LUBERR DX is a DC operated piston pump with the pumping element. It runs from a camshaft connected to a motor box. It can be fitting with up to 3 pumping elements which are available with a PRV (pressure relief valve). The pumping unit plunger sucks the grease from the reservoir and is forced out by pumping unit plunger movement. By this pressure, the grease is forced out from the outlet to the distributors inlet and finally to greasing points. LDX has different reservoir compare to LBX.

LUBERR DX is a DC operated piston pump with the pumping element. It runs from a camshaft connected to a motor box. It can be fitting with up to 3 pumping elements which are available with a PRV (pressure relief valve). The pumping unit plunger sucks the grease from the reservoir and is forced out by pumping unit plunger movement. By this pressure, the grease is forced out from the outlet to the distributors inlet and finally to greasing points. LDX has different reservoir compare to LBX.

The main body of the pump is made from high performance robust plastic and is compact in size designed to withstand tough environments.

The grease version of the LUBERR DX includes a stirrer device with a reservoir wiper that help to eliminate air present in the grease and facilitate pumping even at lower temperatures.

The DC geared motor drive arrangement, is controlled remotely in the manual version or via the built in control system in the automatic version.

LUBERR FX is a DC operated piston pump with the pumping element. It runs from a camshaft connected to a motor box. It can be fitting with up to 3 pumping elements which are available with a PRV (pressure relief valve).

LUBERR FX is a DC operated piston pump with the pumping element. It runs from a camshaft connected to a motor box. It can be fitting with up to 3 pumping elements which are available with a PRV (pressure relief valve).

The main body of the pump is made from high performance robust plastic and is compact in size designed to withstand tough environments.

The grease version of the LUBERR FX includes a reservoir follower assembly that helps to push the grease and facilitate pumping even at lower temperatures.

The DC geared motor drive arrangement, is controlled remotely in the manual version or via the built in control system in the automatic version.

LCX:

CART LUBERR is a DC operated piston pump with the pumping element. It runs from a camshaft connected to a motor box. It can be fitting with up to 30 pumping elements which available without a PRV (pressure relief valve).

CART LUBERR is a DC operated piston pump with the pumping element. It runs from a camshaft connected to a motor box. It can be fitting with up to 30 pumping elements which available without a PRV (pressure relief valve).

The main body of the pump is made from high performance robust plastic and is compact in size designed to withstand tough environments.

The grease version of the CART LUBERR that helps to eliminate dust particle present in the grease and facilitate pumping even at lower temperatures. This version has come with cartridges which contains 1.5 kg amount of grease and replaceable one.

The DC geared motor drive arrangement, is controlled remotely in the manual version or via the built in control system in the automatic version.

OLDX:

OCTO LUBERR is a DC operated piston pump with the pumping element. It runs from a camshaft connected to a motor box. It can be fitting with up to 32 pumping elements. This pump has 4 different varieties of pumping units.

OCTO LUBERR is a DC operated piston pump with the pumping element. It runs from a camshaft connected to a motor box. It can be fitting with up to 32 pumping elements. This pump has 4 different varieties of pumping units.

The main body of the pump is made from high performance Aluminum and is compact in size designed to withstand tough environments.

The grease version of the OCTO LUBERR includes a stirrer device with a reservoir wiper that helps to eliminate air present in the grease and facilitate pumping even at lower temperatures.

The DC geared motor drive arrangement, is controlled remotely in the manual version or via the built in control system in the automatic version.

The LUBERR LBA-3 is a 3 phase AC motorised operated grease pump. LBA-3 is high pressure pump delivering commercial greases up to NLGI class-2. This is a reciprocating type pump carries the lubricating grease to the lubricating point via a progressive distributor or injectors. It is suitable for operating with mineral oil and grease upto a consistency of NLGI grade-2.

It must be ensured that the oil or grease used do not have a tendency to change their consistency-significantly in the course of time or under the influence of temperature or pressure. There can be a maximum of 3 pumping units fitted on the pump. The output from each pumping unit can be fed to the progressive distributors or injectors to various greasing points on the machinery.

MOTOLUBERR:

The MOTOLUBERR is a motorized operated grease pump. It is a high pressure pump delivering commercial greases up to NLGI class-2. This is a reciprocating type pump carries the lubricating grease to the lubricating point via a progressive distributor or injectors. It is suitable for operating with mineral oil and grease upto a consistency of NLGI grade-2. It must be ensured that the oil or grease used do not have a tendency to change their consistency-significantly in the course of time or under the influence of temperature or pressure.

The eccentric movements in pump body push the pump elements pistons and pull as return. This pumping action sucks the grease from the reservoir to pump via suction pipe and is pressurized by piston movement. By this pressure the grease is forced out from the outlet thru the greasing gun or distributors and finally to greasing points. Pumps are made for lubrication purposes only and cannot run continuously over 2 hours. The pump can be used with Progressive distributors / Injectors on any machinery to lubricate various bearing.

MLA:

The MOTOLUBERR MLA-3 is a 3 phase AC motorised operated grease pump.

| MOTOR TYPE | 380 VAC to 440 VAC |

| Max Operating Pressure | 280 Bars |

| PROTECTION CLASS | IP-55 |

| OUTPUT | 60 GMS/MIN at 200 bar |

| Working Temperature | -10°c Upto +70°c |

| RESERVOIR CAPACITY | 20 KG DRUM |

| Lubricant | Max upto NLGI grade 2 |

The MOTOLUBERR MLD (Motoluberr Deluxe) is a DC operated grease pump. Motor type is 24 VDC geared motor (15 Amps rated). It has different capacity 20 kg and 50 kg reservoir. Its maximum working pressure is 300 bars. MLD comes without low level indicator (standard), with low level indicator, with low level switch. Motoluberr Deluxe contains Timer control unit or SMPS 230 VAC converter. Here serial line distributing systems are used.

The MOTOLUBERR MLD (Motoluberr Deluxe) is a DC operated grease pump. Motor type is 24 VDC geared motor (15 Amps rated). It has different capacity 20 kg and 50 kg reservoir. Its maximum working pressure is 300 bars. MLD comes without low level indicator (standard), with low level indicator, with low level switch. Motoluberr Deluxe contains Timer control unit or SMPS 230 VAC converter. Here serial line distributing systems are used.

MLI:

The MOTOLUBERR MLI (Motoluberr with Injector) is a DC operated grease pump. Motor type is 24 VDC geared motor (15 Amps rated). It has capacity of 25 kg reservoir. Its maximum working pressure is 300 bars. MLD comes without low level indicator (standard), with low level indicator, with low level switch. Motoluberr with Injector system contains Timer control unit or SMPS 230 VAC converter. Here parallel line injector systems are used.

The MOTOLUBERR MLI (Motoluberr with Injector) is a DC operated grease pump. Motor type is 24 VDC geared motor (15 Amps rated). It has capacity of 25 kg reservoir. Its maximum working pressure is 300 bars. MLD comes without low level indicator (standard), with low level indicator, with low level switch. Motoluberr with Injector system contains Timer control unit or SMPS 230 VAC converter. Here parallel line injector systems are used.

MLG:

The MOTOLUBERR MLG (Motoluberr Garage) is a DC operated grease pump. Motor type is 24 VDC geared motor (15 Amps rated). It has different capacity 20 kg and 50 kg reservoir. Its maximum working pressure is 300 bars. MLG comes without low level indicator (standard), with low level indicator, with low level switch. Motoluberr Garage contains Timer control unit, SMPS 230 VAC converter or ON/OFF switch. Especially this pump is useful for refilling the Grease pump (LUBERR) in Industries/ Garages where stationary filling required.

OXL:

OXYLUBERR is developed by Rikkon Lubes to provide reliable and efficient Lubrication Systems on mobile application (mining Industry). OXYLUBERR was developed keeping in mind various kinds of Ambient. LUBERR has been tested at -10 deg C to +70 deg C. OXYLUBERR is tested at harshest of environment like most dusty and terrain. This pump is a PNEUMATICALLY Operated High Pressure Grease pump. OXYLUBERR has max 1 output and has a grease holding capacity of 50 kgs. It is a 50:1 ratio pump capable of pumping grease upto 100 mts long distance. The size of the pump is ideally designed to reduce the air consumption during operation. OXYLUBERR comes with Quick Fill fitted at the bottom of the reservoir.

OXYLUBERR is developed by Rikkon Lubes to provide reliable and efficient Lubrication Systems on mobile application (mining Industry). OXYLUBERR was developed keeping in mind various kinds of Ambient. LUBERR has been tested at -10 deg C to +70 deg C. OXYLUBERR is tested at harshest of environment like most dusty and terrain. This pump is a PNEUMATICALLY Operated High Pressure Grease pump. OXYLUBERR has max 1 output and has a grease holding capacity of 50 kgs. It is a 50:1 ratio pump capable of pumping grease upto 100 mts long distance. The size of the pump is ideally designed to reduce the air consumption during operation. OXYLUBERR comes with Quick Fill fitted at the bottom of the reservoir.OXYLUBERR can be controlled using a Controller which can be fitted at a distant convenient location. Output from OXYLUBERR is distributed to various points using SVM 21 Progressive Distributors (for series system) or SVM01 INJECTORS (for parallel System).

SVM 21:

The Rikkon Lube Progressive Distributor Model SVM 21DV are plunger operated distributors suitable for operating with mineral oil and grease upto a consistency of NLGI grade-2. It must be ensured that the oil or grease used do not have a tendency to change their consistency-significantly in the course of time or under the influence of temperature or pressure. These plunger displacement distributors automatically (Progressively) deliver the lubricant fed by the pump into preset individual volumes to the connected lubrication point.

MODE OF OPERATION

- The input of the lubricant to the progressive unit can be continuous or intermittent.

- The output of the division of progressive units is volumetric. i.e.) every movement of the plunger delivers a fixed quantity of lubricant.

- The progressive unit repeats its cycle as long as the lubricant is supplied to the inlet port.

- If the supply is stopped and restarted the unit would operate from the place where it had stopped previously.

- Each plunger must complete its full movement before the following plunger can be moved.

- The external obstructions in the user supply lines causes the plunger to stop and this would result in failure of the units. The failure of any one of the units causes the complete system to shut down. This facility can be monitored by using proximity or limit switch provided on any one of the units in the system.

The Rikkon Lube Progressive Distributor Model SVM 23A are plunger operated distributors suitable for operating with mineral oil and grease upto a consistency of NLGI grade-2. It must be ensured that the oil or grease used do not have a tendency to change their consistency-significantly in the course of time or under the influence of temperature or pressure. These plunger displacement distributors automatically (Progressively) deliver the lubricant fed by the pump into preset individual volumes to the connected lubrication point.

MODULAR PROGRESSIVE DISTRIBUTOR SVM 23A

MODE OF OPERATION

MODE OF OPERATION

- The input of the lubricant to the progressive unit can be continuous or intermittent.

- The output of the division of progressive units is volumetric. i.e.) every movement of the plunger delivers a fixed quantity of lubricant.

- The progressive unit repeats its cycle as long as the lubricant is supplied to the inlet port.

- If the supply is stopped and restarted the unit would operate from the place where it had stopped previously.

- Each plunger must complete its full movement before the following plunger can be moved.

- The external obstructions in the user supply lines causes the plunger to stop and this would result in failure of the units. The failure of any one of the units causes the complete system to shut down. This facility can be monitored by using proximity or limit switch provided on any one of the units in the system.

SVM53 -SPRAY SYSTEM:

The Rikkon Lube spray Pump Model SVM53 is compact pump which spray oil up to cst100. This is a reciprocating type pump which carries the oil to the lubricating point via a coaxial tube. The air passes thru the solenoid valve to the pump outlet and travels along with the oil in the coaxial tube. The air and oil gets mixed at the end of the coaxial tube where the lubricant to be sprayed. Capacity of the reservoir is 2.0Lts. Larger capacity reservoirs can be provided on request.

The Rikkon Lube spray Pump Model SVM53 is compact pump which spray oil up to cst100. This is a reciprocating type pump which carries the oil to the lubricating point via a coaxial tube. The air passes thru the solenoid valve to the pump outlet and travels along with the oil in the coaxial tube. The air and oil gets mixed at the end of the coaxial tube where the lubricant to be sprayed. Capacity of the reservoir is 2.0Lts. Larger capacity reservoirs can be provided on request.

SALIENT FEATURES:

- As the pump is switched ON, the pump element starts to deliver the oil as per the timer. The spool reciprocates to deliver the oil.

- The air gets mixed at the end of coaxial tube at the nozzles.

- The air pressure can be individually controlled for each spray.

- The timer can be adjusted for On time and Off time. This decides the output of oil from each outlet.